Products

Contact us

Edna Yang

Tel: +86-510-8525-9383

Cell: +86-151-5221-3005

Email: edna.yang@bolibio.com

Jiangsu Boli Bioproducts Co.,Ltd.

Add: 93 Yangzhou Road, Jiangyan Economic Development Zone, Jiangsu 225500, China

Jiangsu Boyang Bioproducts Co., Ltd.

Add: 30 Tongwang Road, Nantong Economic Development Zone, Jiangsu 226010, China

Product Description

Description

Glucoamylase GA-1000 is a powder preparation made from selected strains of Aspergillus niger using submerged fermentation, extraction and refining techniques. GA-1000 has a high conversion rate of starchy substrates into fermentable sugars. It can hydrolyze α-D-1, 4 glucosidic bonds from the non-reducing end of starch one after another. It can also hydrolyze the α-D-1, 6 glucoside branch bonds of starch and cleaves the α-1, 3 bonds, releasing glucose.

GA-1000 has been especially designed for saccharification in ethanol production. Use of GA-1000 provides higher ethanol yields, faster fermentations, and lower residual starch levels.

Product Characteristics

|

Declared Enzyme:

|

Glucoamylase

|

|

Systematic Name:

|

EC 3.2.1.3, 1,4-alpha-D-glucan glucohydrolase

|

|

Appearance:

|

Light to dark brown powder

|

|

Activity:

|

100,000 U/g (minimum)

|

|

Moisture

|

≤8%

|

Effect of pH

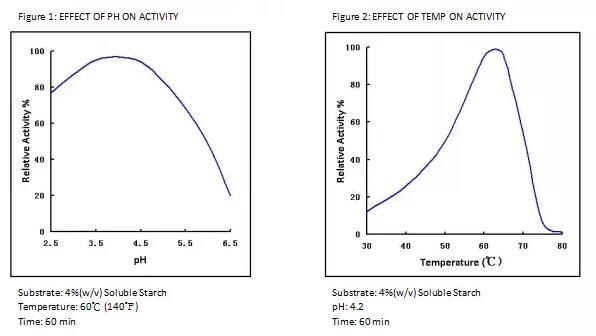

Effective pH range for GA-1000 is 3.0 to 5.5. For maximum activity, the optimal pH is from 3.5 to 4.5. See Figure 1.

Effect of Temperature

Generally, the temperature range for GA-1000 is 30 to 65°C. The optimal temperature range is 55 to 60°C. See Figure 2.

Applications

GA-1000 is used to saccharify liquified mash from various sources including corn, milo, barley, wheat, rice, potatoes and tapioca. The resultant glucose product is fermented by yeast or another appropriate microorganism to yield ethanol.

GA-1000 is designed to ensure the following benefits:

- Increased fermentation rate

- Increased ethanol yields

- Efficient starch/dextrin degradation

- Less residual starch in distiller’s grains

- Improved performance in pre-saccharification processes

For ground-grain processing plants using simultaneous saccharification fermentation (SSF), GA-1000 may be added directly to the fermenter. For ground-grain dry mill plants and for wet mill plants using a separate pre-saccharification step prior to fermentation, GA-1000 may be added to the cooling mash or liquefied starch when the temperature reaches 55 to 60°C. Temperatures above 65°C can result in loss of activity.

GA-1000 should be dissolved in 25~30°C warm water at a recommended ratio of 1:10 (enzyme: water) prior to use it.

Dosage Guidelines

GA-1000 is generally added at a level of 1.05 to 1.35kg/TDS. The actual enzyme requirement is dependent on the raw materials, temperature, reaction time, and pH of the individual plant saccharification/fermentation process, and its desired result.

Packaging

GA-1000 is packaged in 25kg cardboard drums or 20kg kraft paper bags. Customized packaging is available upon request.

Storage

- This enzyme has been formulated for optimal stability.

- Typical shelf-life is eighteen months provided it is stored below 25°C in its original packaging, sealed and unopened, protected from the sunlight.

- Prolonged storage and/or adverse conditions such as higher temperatures may lead to a higher dosage requirement.

Safe Handling of Enzymes

Inhalation of enzyme dust and mists should be avoided. In case of contact with the skin or eyes, promptly rinse with water for at least 15 minutes. For detailed handling information, please refer to the appropriate Material Safety Data Sheet.

Previous

Next

Previous

Next

Online message