Products

Contact us

Edna Yang

Tel: +86-510-8525-9383

Cell: +86-151-5221-3005

Email: edna.yang@bolibio.com

Jiangsu Boli Bioproducts Co.,Ltd.

Add: 93 Yangzhou Road, Jiangyan Economic Development Zone, Jiangsu 225500, China

Jiangsu Boyang Bioproducts Co., Ltd.

Add: 30 Tongwang Road, Nantong Economic Development Zone, Jiangsu 226010, China

Acid Protease AP-500

Category:

Product Description

Description

Acid Protease AP-500 is a food grade acid protease enzyme produced from Aspergillus niger through submerged fermentation, extraction, and refining processes. AP-500 can effectively hydrolyze proteins under acidic conditions. Applications for using AP-500 include: potable alcohol, food and beverage industries where protein hydrolysis is needed under low pH conditions.

Product Characteristics

|

Declared Enzyme:

|

Acid Protease

|

|

Systematic Name:

Activity:

|

EC 3.4.23.18

50,000 U/ml (minimum)

|

|

Appearance:

|

Sepia brown Liquid

|

|

Product pH

|

2.5~5.0

|

|

Specific gravity

|

≤ 1.25 g/ml

|

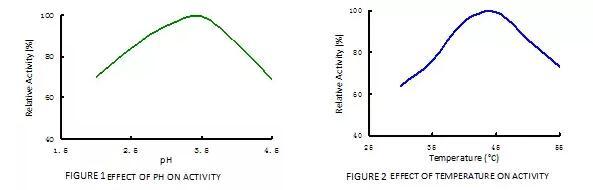

Effect of pH

The effective pH range for the activity of AP-500 is approximately 2.0 to 6.0, with an optimum performance at pH 2.5 to 3.5. See Figure 1.

Effect of Temperature

The activity of AP-500 is effective in the range from 30°C to 65°C (86℉ to 149℉), with an optimum performance obtained at 40℃ to 50°C (104℉ to 122℉). The exact temperature optimum will be influenced by several process variables including time, pH, and substrate nature and substrate concentration. See Figure 2.

Effect of Metal Ions

AP-500 is activated by Mn2+, Ca2+ and Mg2+ ions. Heavy metal ions such as Cu2+, Hg2+ and Al3+ will inhibit AP-500 enzyme.

Benefits

Use of AP-500 in fermentation process offers the following benefits:

Promotes improved fermentation ,saccharification and oil extraction

AP-500 can hydrolyze the proteins present in the raw materials, destroying the interstitial cell wall structure of starch granules, thereby releasing the starch wrapped in the granules, resulting in improved saccharification as well as freeing bound oil.

Promotes enhanced yeast growth

Free Amino Nitrogen (FAN) is the most effective nitrogen source for yeast. The addition of AP-500 during alcoholic fermentation can effectively hydrolyze proteins and peptides in the raw materials so as to generate FAN that the yeast can absorb. The absorption of the free amino nitrogen promotes yeast growth, increases the quantity of yeast in the fermented mash, and shortens the fermentation cycle.

Promotes higher alcohol yields

The use of AP-500 in the propagation and/or fermentation steps to form Free Amino Nitrogen (FAN) can not only shorten the fermentation cycle but also increase the output of alcohol, improve alcohol tolerance and survival rate of yeast.

Reduces urea/ammonia usage

The increased FAN produced by use of AP-500 may result in a reduced need for urea/ammonia addition. Exact reduction levels will need to be determined based upon fermentation results.

Applications

In intermittent fermentations, the entire dose of AP-500 should be added all at once after the fermentation tank is filled approximately 30%. In continuous fermentations, AP-500 should be added continually, with the dosage rate dependent on the amount of mash fed at the inlet of the fermentation tank.

Dosage Guidelines

The typical dosage rate for AP-500 is 0.02% to 0.04% w/w (dry solids basis) and this dosage level is recommended as a starting point for optimizing the enzyme dosage. The optimum enzyme dosage will be dependent on both the raw materials used (substrate nature and concentration) and the processing conditions.

Packaging

AP-500 is available in 25kg or 30kg plastic containers and 1125kg IBC totes. Customized packaging is available upon request.

Storage & Shelf-life

- AP-500 has been specially formulated for optimal stability.

- Typical shelf-life is twelve months if this product is stored properly at <25°C(77oF).

- Prolonged storage at higher temperatures may lead oto higher dosage , therefore should be avoided.

Safe Handling of Enzymes

Inhalation of enzyme dust and mists should be avoided. Proteins present in the AP-500 may cause an allergic-type reaction in sensitized individuals which could necessitate immediate medical attention. In case of contact with the skin or eyes, promptly rinse with water for at least 15 minutes. For detailed handling information, please refer to the Safety Data Sheet.

Previous

Next

Previous

Next

Online message